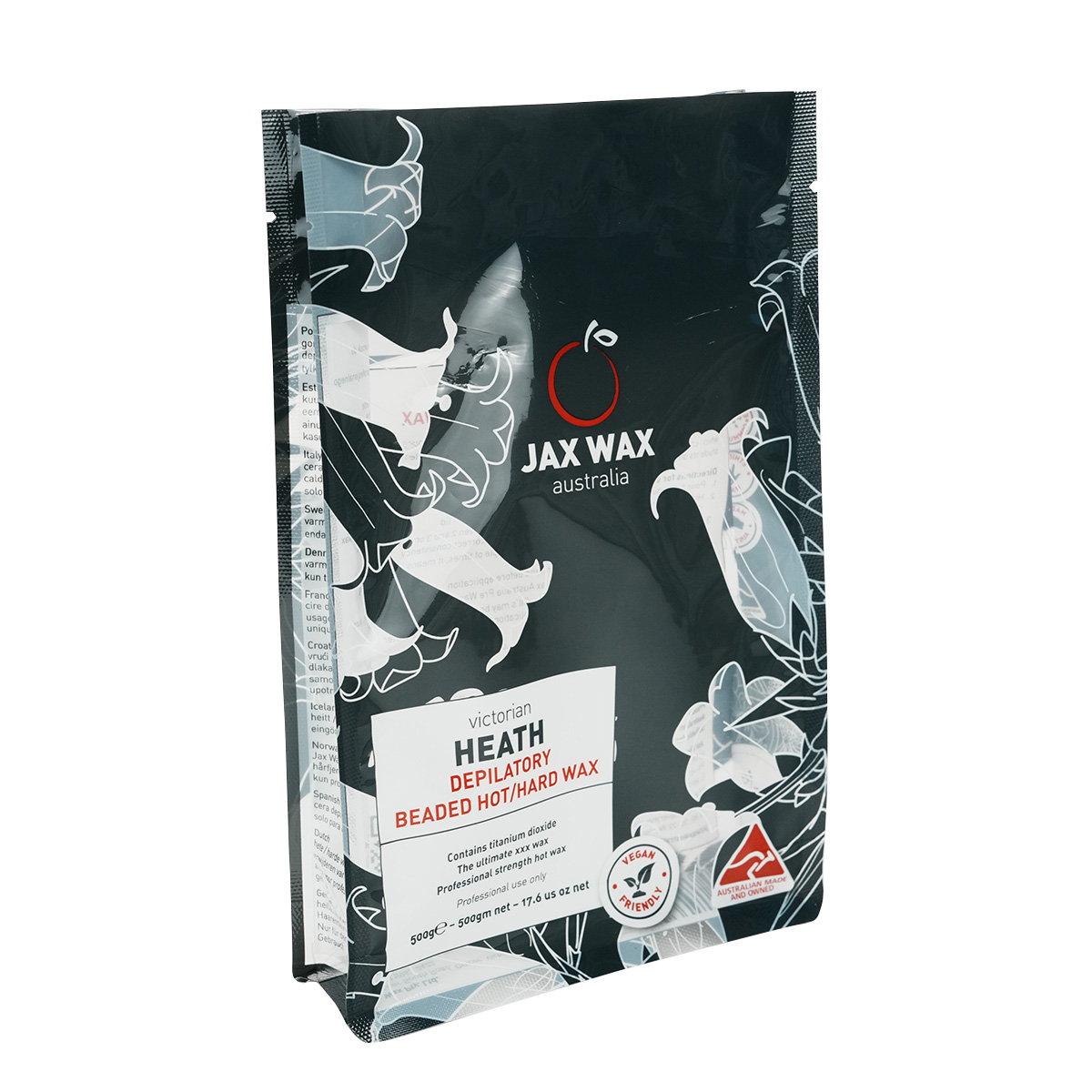

Custom Vacuum Pouches from Trusted Suppliers - Quality Packaging Solutions

When I think about enhancing product freshness and extending shelf life, I can't help but recommend my vacuum pouches. These custom solutions are perfect for businesses looking to secure their goods with a reliable barrier against moisture, air, and contaminants. As a supplier, I understand the importance of quality packaging, and our vacuum pouches are designed to meet the diverse needs of various industries. Whether you're in food production, pharmaceuticals, or any other sector, my custom vacuum pouches come in various sizes and thicknesses to suit your requirements. By using our pouches, you’ll not only improve the durability of your products but also enhance their presentation. The seamless sealing technology ensures no air pockets, keeping your items fresh. With competitive prices and quick turnaround times, I’m confident you’ll find the perfect packaging solution that aligns with your business goals. Let’s take your packaging game to the next level!

Vacuum Pouches Pioneers in the Field Factory-Direct Excellence

In the ever-evolving landscape of packaging solutions, vacuum pouches have emerged as a game-changing innovation, offering unparalleled preservation and protection for a wide array of products. Factory-direct excellence in the production of these pouches not only ensures superior quality but also fosters strong relationships between manufacturers and global buyers. By eliminating middlemen, businesses can enjoy significant cost savings while receiving freshly manufactured products tailored to meet their specific needs. At the forefront of this industry, manufacturers are investing in advanced technologies and sustainable practices to enhance the reliability and functionality of their vacuum pouches. With options available for customized sizes, materials, and designs, businesses can effectively prolong shelf life, maintain flavor integrity, and minimize waste. As more companies recognize the benefits of vacuum packaging, partnering with a reliable supplier can be key to gaining a competitive edge in the market. The demand for high-quality vacuum pouches continues to rise across various sectors, from food and beverage to pharmaceuticals and electronics. It is crucial for global buyers to align with manufacturers who prioritize innovation, quality control, and customer satisfaction. By leveraging factory-direct relationships, businesses can secure not only top-notch products but also strategic insights into market trends, ensuring they stay ahead in a competitive landscape.

Vacuum Pouches Pioneers in the Field Factory-Direct Excellence

| Material | Thickness (microns) | Applications | Sealing Method | Temperature Resistance |

|---|---|---|---|---|

| Nylon | 100 | Food Packaging | Heat Sealing | -40°C to 90°C |

| Polyethylene | 80 | Medical Supplies | Impulse Sealing | -30°C to 80°C |

| Polyester | 150 | Consumer Goods | Vacuum Sealing | -50°C to 120°C |

| Polypropylene | 75 | Electronics Packaging | Heat Sealing | -20°C to 85°C |

Related Products

Vacuum Pouches Now Trending Service Backed by Expertise

Top Selling Products

-

Phone

Phone

86 13502997386

86 13682951720 -

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top